Top 5 IT Hardware Procurement Challenges and How to Navigate Them

IT hardware procurement is far more complex than placing an order.

Get it wrong and you’ll feel the impact in lost team productivity, missed onboarding deadlines, and unexpected hits to your bottom line.

Supply chain delays can leave employees sitting idle, and unreliable vendors can risk device quality. And before you know it, you’ll end up with hidden costs that quietly wreck your budget.

But you can avoid these challenges with the right strategies.

In this article, I’ll break down the top IT hardware procurement challenges and share practical strategies to help you overcome them. I’ve also included a checklist so you don’t miss out on steps during IT procurement.

TL;DR:

- Global logistics disruptions can stall shipments. Try to plan ahead, keep local buffers, and use platforms like Workwize with regional warehouses to stay on schedule.

- Unreliable vendors inflate costs through downtime, poor warranty, and mismatched hardware. Try to vet suppliers for quality, global reach, and service SLAs.

- Don’t rely on the sticker price alone. Factor setup, repair, and disposal into your Total Cost of Ownership (TCO) to prevent budget overruns.

- Refresh devices every 3–5 years, align warranties, and adopt leasing or DaaS models to avoid obsolescence and downtime.

- Educate stakeholders, standardize workflows, and automate approvals to prevent maverick spending and process bottlenecks.

- Workwize, with its end-to-end IT hardware management capabilities, simplifies everything from vendor vetting to global shipping, budgeting, and asset disposal.

Challenge 1: Supply-Chain Delays and Global Logistics

Logistical challenges are commonplace, especially when you have a globally distributed team. The primary reason is that there are factors beyond your control at play.

For instance, data states that 8-10% of the global container fleet was delayed in early 2025. And the common reasons behind such delays include port congestion, geopolitical instability, low sea water levels, rogue elements (Houthi rebels), among other factors.

These delays mean your new hires might not receive their equipment (laptop, computer, keyboard) on time, resulting in a significant productivity loss.

With the average U.S. software developer earning $130,000 a year, even a single lost day costs around $500. And this number multiplies quickly across teams and longer delays.

But you can minimize the possibility of these delays impacting the delivery of your IT hardware.

How to Navigate This?

Here’s a practical strategy to handle supply chain delays and global logistics:

-

Plan and Buffer

Forecast your IT hardware needs as early as possible. For instance, you can initiate orders well before you expect a hardware refresh cycle or hiring surge.

Even if shipments are delayed due to factors beyond your control, your buffer buys you time and mitigates the impact of slow shipments.

-

Use Local Suppliers or Warehouses

Choose a supplier with global coverage and local warehousing to cut down transit times.

Workwize solves this problem for teams of all sizes. With its global ITAM solution, you can source, procure, and ship IT equipment across 100+ locations worldwide.

Workwize’s network of local warehouses in multiple countries means assets are shipped within the employee’s region. This helps you bypass cross-border shipping delays, avoid customs issues, and cut down on expensive shipping fees.

-

Streamline Internally

Global logistics are hard enough. Don’t let internal delays make them worse.

Analyze your procurement workflow to identify potential bottlenecks.

Let’s assume you found that the approval process is manual. You can automate approval steps and consolidate purchase requests to avoid internal delays.

If you have a distributed team, try using a centralized platform like Workwize to:

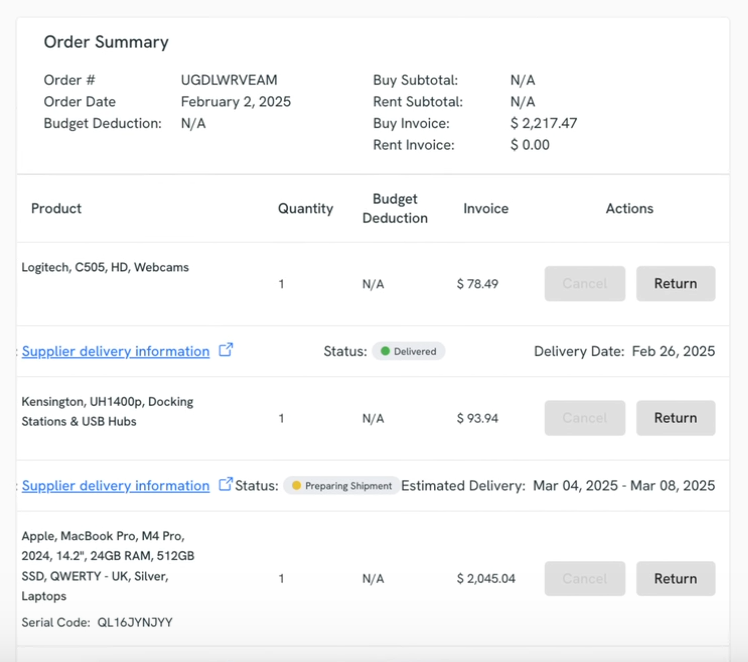

- Track all shipments in real-time: Workwize lets you see all your orders in one place and track them in real-time:

- Coordinate delivery with the employee's start date: The HR can trigger an automated onboarding workflow with the employee’s start date and make sure the necessary hardware is delivered on time.

- Automate approvals: You can automate approvals for some devices and save yourself from manual effort.

Challenge 2: Vendor Quality and Reliability

Unreliable vendors will only take you so far. According to a survey conducted by Molex, 91% tech leaders believe you need trusted and proven suppliers to build reliable products.

If you choose vendors based on who offers the lowest quote, you might be compromising on vendor quality and reliability.

Poor vendor quality and reliability can impact IT hardware procurement in more ways than you can imagine, including:

- Inconsistent Device Configurations: Low-quality vendors may swap out original components for cheaper generic ones, creating performance issues, compatibility problems, and more frequent device failures. This shortens refresh cycles and inflates costs.

- Varying Warranty & Support Services: You may experience excellent warranty and support services with some vendors, while others may offer none.

- Vendor Lock-in: Imagine being locked in with a vendor for years, even when they’re jacking up the prices every few months.

- Geographic Gaps: Global teams may face delays if the vendor has no local stock or lacks global coverage, which can undo your onboarding timelines.

How to Navigate This?

Here’s how you can ensure vendor quality and reliability:

-

Choose Vendors Wisely

The cheapest quote isn’t always the cheapest long-term option. Here’s what to look out for instead:

- Evaluate suppliers on their track record and capabilities: Check customer references, case studies, and independent reviews.

- Look for certifications or references that attest to their quality control: ISO 9001 for quality management, ISO 27001 for security, and R2v3 for responsible recycling are good indicators of maturity.

- Global Footprint: Can they deliver and support devices in every region where you have employees?

Pro Tip: Partnering with IT Asset Management (ITAM) solutions, like Workwize, gives you an edge. Instead of vetting vendors yourself, you get access to a global network of suppliers already screened for:

-

Standardize Hardware Specs Globally

Create a standard hardware profile that includes specific approved models or configurations and requires your vendors to meet those requirements. This ensures the software developer in California gets a laptop with the same specs as the developer in São Paulo.

While standardization is essential, don’t forget to respect distinct requirements.

One of Workwize’s clients encountered an issue when their previous logistics partner shipped European plugs to both their Irish and Portuguese staff without an adapter and their Portuguese staff. This situation created avoidable delays, resulting in wasted time and money.

So, try to avoid these kinds of standardizations.

-

Set Clear SLAs and Monitor Performance

Treat your vendor relationships as ongoing partnerships. Set service level agreements (SLAs) for:

- Delivery times

- DOA (dead on arrival) rates

- Warranty support

- Global footprint: Can they deliver and support devices in every region where you have employees?

Then, monitor these metrics consistently using supplier scorecards that track on-time delivery, defect rates, and support responsiveness. Gartner claims their supplier scorecard improves supplier performance.

And if a supplier misses SLAs repeatedly, re-negotiate terms or consider switching suppliers

Pro Tip: Conduct quarterly business reviews (QBRs) with your suppliers to discuss delivery performance, defect trends, and support responsiveness. QBRs create a feedback loop that keeps vendors accountable, ensures issues are addressed before they escalate, and strengthens your procurement process over time.

Challenge 3: Budget Control and Hidden Costs

There’s always a budget that IT or procurement managers have to adhere to. Yet in practice, the actual cost almost always surpasses this defined budget.

In fact, data show that procurement costs are always 30-40%, or sometimes several times higher than reported. But why does this happen? Well, hidden costs!

Imagine you ordered five laptops worth $500 each. You’d expect to spend a total of $2500, but what about these hidden expenses:

- Repair costs

- License fee

- Cost of setting up the device

- Costs of consumables

- Spare parts

Because these costs are often billed individually across different departments, they slip under the radar.

But from a procurement perspective, all these costs add up to form the total cost of ownership (TCO).

Failing to factor these hidden costs in has major consequences:

- You might run out of budget for other IT initiatives or settle for lower-quality IT equipment.

- All your negotiations would be pointless if the money you saved were to be spent on an expedited shipping fee or an emergency repair.

- Poor cost control might raise questions about the procurement team’s credibility.

- Worst case: you might end up with half-deployed equipment or maintenance contracts you cannot afford to renew.

How to Navigate This?

Here’s what you can do to implement effective budget control:

-

Factor in the Total Cost of Ownership (TCO)

Stop considering the price tag on your IT hardware as the final price. Factor in costs like deployment labor, support, power consumption, and end-of-life disposal fees before making a purchase.

Sometimes, a product that seems cheap upfront might incur higher repair costs. On the flip side, a pricier product could be more cost-effective in the long run if it’s more durable and cheaper to maintain.

-

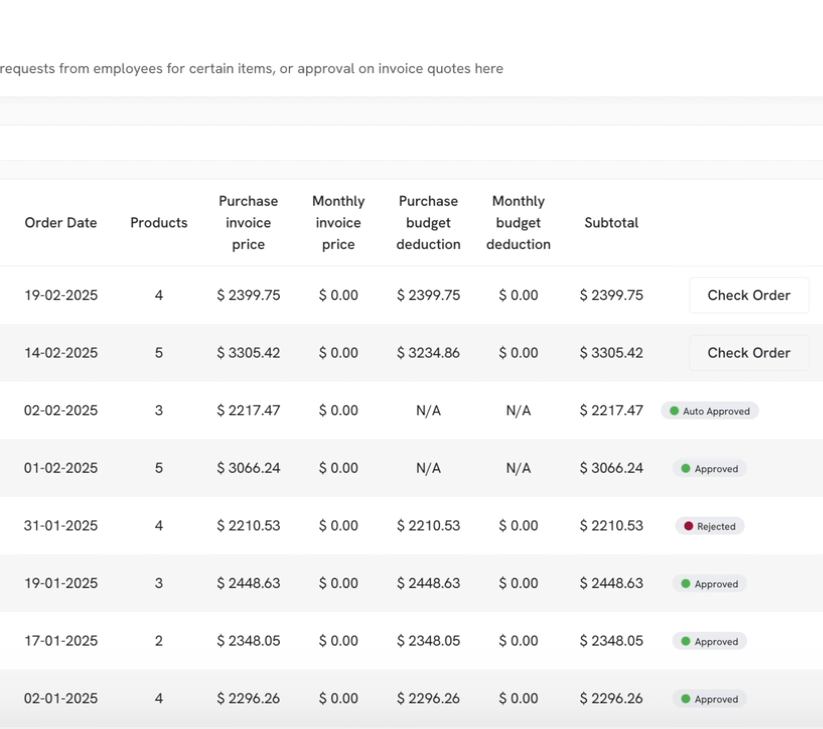

Implement Spend Controls and Visibility

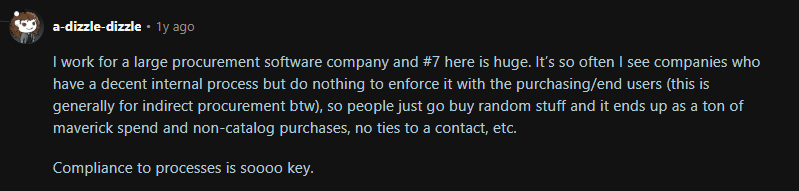

Create and enforce department-wise spending limits and alerts. This will help you avoid maverick spending, a major challenge companies face. Here’s a Reddit user who shares how failing to enforce internal processes leads to maverick spending and non-catalog purchases:

Source: Reddit

Also, maintain a centralized view of all procurement costs. If your data sits in silos (hardware costs in one system, shipping on another, and repairs in a third), you’re bound to miss the bigger picture.

-

Negotiate Full-Package Deals

Try negotiating bundled deals with your vendors that include free or discounted shipping, extended warranties, or bulk purchase rebates. Some vendors might even agree to offer free installation or training as part of large deals.

These value-add-ons that go beyond the unit price can significantly reduce your out-of-pocket costs in the future.

-

Monitor and Adjust

Compare actual spending against the forecast.

For instance, if the electricity consumption of your servers is 10% more than expected, factor that in your future budgets. Or, if the maintenance costs spike, invest in more robust hardware. Over time, this continuous feedback loop keeps procurement both realistic and credible.

Challenge 4: Rapid Obsolescence

Tech moves fast; sometimes faster than your budget. Even top-of-the-line laptops and computers age quickly, become costly to maintain, and eventually risky.

According to HP, a well-maintained laptop lasts anywhere between 3 and 5 years, and a computer lasts between 3 and 8 years. Acer estimates that maintaining devices older than 4 years costs about $1525 per device. We’re not even talking about the productivity losses, yet from crashes, slowdowns, or software incompatibility.

And when devices stop receiving critical security updates, they turn into ticking time bombs. This can leave vulnerabilities unpatched and expose your company to breaches.

How to Navigate This?

Mastering obsolescence means treating hardware as a continuous lifecycle rather than a one-off purchase. Here’s how to stay ahead:

-

Plan Refresh Cycles Proactively

Create an internal hardware refresh policy—laptops get replaced every 4 years and desktops every 5, etc. You can also implement rolling refreshes, replacing 20-25% of the total assets annually, to ensure no device exceeds the recommended age.

Pro Tip: Align warranties with your refresh cycles. If you plan to replace your laptops every 5 years, consider buying a 5-year warranty to cover repairs.

-

Monitor Performance

Continuously monitor device performance. If you notice that device support tickets are rising for a certain device model, or older devices are causing issues with software rollouts, it might be time to replace them.

-

Have An End-of-Life Plan

Develop a strategy to handle the end-of-lifecycle devices in a responsible manner. You can do these things:

- Automate certified data erasure (NIST 800-88 compliant).

- Decide on the final route: donation, resale, recycling, or destruction.

- Capture serial numbers, certificates of destruction, and chain-of-custody records for compliance and ESG reporting.

Pro Tip: Partnering with ITAM solutions like Workwize comes with the perk of automated asset disposal. You can retrieve end-of-life assets from your users using Workwize and decide what you need done, i.e., eco-friendly disposal or donation. Whatever the case, Workwize will perform a certified data erasure to ensure your data stays protected.

-

Consider New Ownership Models

Buying new hardware outright every few years can be expensive and inefficient.

Leasing models or Device-as-a-Service (DaaS) programs can spread costs, simplify refresh cycles, and ensure employees always have up-to-date machines.

Instead of buying new assets every few years, try leasing IT equipment from providers like Workwize.

Once the devices become obsolete, Workwize will replace them with newer ones, and at a significantly lower cost than purchasing new assets. This not only helps you fight rapid obsolescence but also prevents you from making huge investments upfront.

Challenge 5: Internal Stakeholder Issues

Internal stakeholder conflict is one of the most underrated IT hardware procurement challenges, but if left unchecked, it can quietly derail your process.

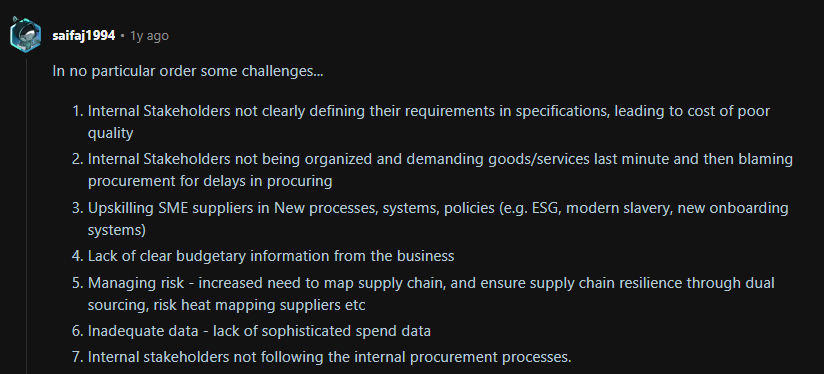

This Reddit user’s thread on IT hardware procurement challenges highlights that lots of the issues raised were internal, not vendor-related.

Source: Reddit

3 out of 7 challenges are related to internal stakeholders, highlighting issues like:

- Poorly defined requirements: Stakeholders often submit vague or incomplete specs, leading to mismatched purchases.

- Last-minute requests: Teams raise urgent purchase requests with zero lead time, forcing IT to rush and overpay for expedited shipping.

- Process bypassing: Employees sidestep procurement rules entirely and buy their own hardware, resulting in maverick spending, inconsistent device fleets, and untracked assets.

These issues can result in internal conflicts, untracked assets, and lost bulk-purchase discount opportunities.

Some Reddit users even say that due to internal conflicts, users end up buying random stuff, resulting in maverick spending. Solution?

How to Navigate This?

To handle stakeholder issues professionally, do this:

-

Educate and Align Stakeholders

Don’t assume everyone understands the “why” behind procurement. Show department heads how following the process saves money, reduces risk, and helps them get the hardware they need faster.

-

Create a Clear Procurement Playbook

Document and publish procurement guidelines that cover how to submit requests, expected lead times, approval workflows, and decision criteria. A transparent playbook reduces friction and last-minute surprises.

-

Standardize and Automate Approvals

Replace manual approvals with automated workflows. This speeds up processing, eliminates bottlenecks, and ensures consistent application of policies.

-

Establish Governance and Accountability

Assign ownership and enforce compliance. Clear roles and accountability prevent stakeholders from bypassing procurement or creating their own rules.

Now that you know about the most pressing IT hardware procurement challenges and how to navigate them, let’s check out some procurement best practices. This will help you naturally avoid procurement mistakes.

IT Hardware Procurement Best Practices

Here are some IT hardware procurement best practices for a smoother and more effective procurement process:

Establish a Clear Procurement Strategy

Create a formal strategy that outlines purchasing policies (centralized vs. decentralized), vendor preferences, and objectives such as cost savings or supplier diversity. Revisit annually to align with evolving business needs and market changes.

Why this matters: A clear roadmap eliminates confusion, boosts compliance, and helps stakeholders see procurement as a strategic partner—not just an order taker.

Perform Needs Assessment & TCO Analysis

Collaborate with stakeholders to confirm actual needs, avoiding over- or under-specifying equipment. Conduct a Total Cost of Ownership (TCO) review that includes support, maintenance, energy use, and end-of-life value—not just sticker price.

Why this matters: This ensures smart budgeting, reduces long-term regret purchases, and gives you stronger justifications for budget approvals.

Leverage AI & Data

Adopt tools to automate repetitive tasks like invoice processing, approvals, and spend tracking. Use AI analytics tools for demand forecasting and to identify supplier consolidation opportunities or unusual cost trends.

Why this matters: Data-driven procurement improves accuracy, saves time, and puts your team ahead of competitors already using AI to optimize procurement.

Implement IT Asset Management (ITAM)

Integrate ITAM tools like Workwize to automate the entire procurement workflow and track devices across their lifecycle—ownership, warranty, utilization, and retirement.

Why this matters: Here’s why:

- With Workwize, procurement teams also gain end-to-end visibility from the moment an asset is ordered.

- Every purchase is logged automatically, helping you stay on budget, track warranties, and manage refresh cycles without manual effort.

- Beyond procurement, Workwize ensures assets are delivered on time, retrieved during offboarding, and disposed of sustainably through certified recycling or reuse.

- This makes Workwize not just a procurement tool, but a complete lifecycle management platform.

This prevents ghost assets, reduces waste, and gives you real-time insights to avoid over-buying or last-minute emergency purchases.

Evaluate Vendors on Risk & Security

Go beyond cost by scoring suppliers on financial stability, compliance, security standards, and supply chain resilience. Build a diverse, vetted pool to minimize single points of failure.

Why this matters: Vendor reliability directly impacts uptime and user satisfaction. Strong evaluation protects against hidden risks, data breaches, and costly supply disruptions.

Centralize Procurement

Adopt a centralized platform like Workwize to manage suppliers, approvals, and purchases globally. Gain visibility into spend and inventory across regions, automate compliance, and cut duplicated orders.

Adopt Sustainability Measures

Set green procurement policies—favor energy-efficient hardware, minimize packaging, and refurbish devices for reuse where possible. Use certified recycling/disposal partners for end-of-life assets.

Why this matters: Sustainability reduces costs, strengthens brand reputation, and meets ESG reporting demands. It also resonates with clients who prioritize ethical and environmentally responsible partners.

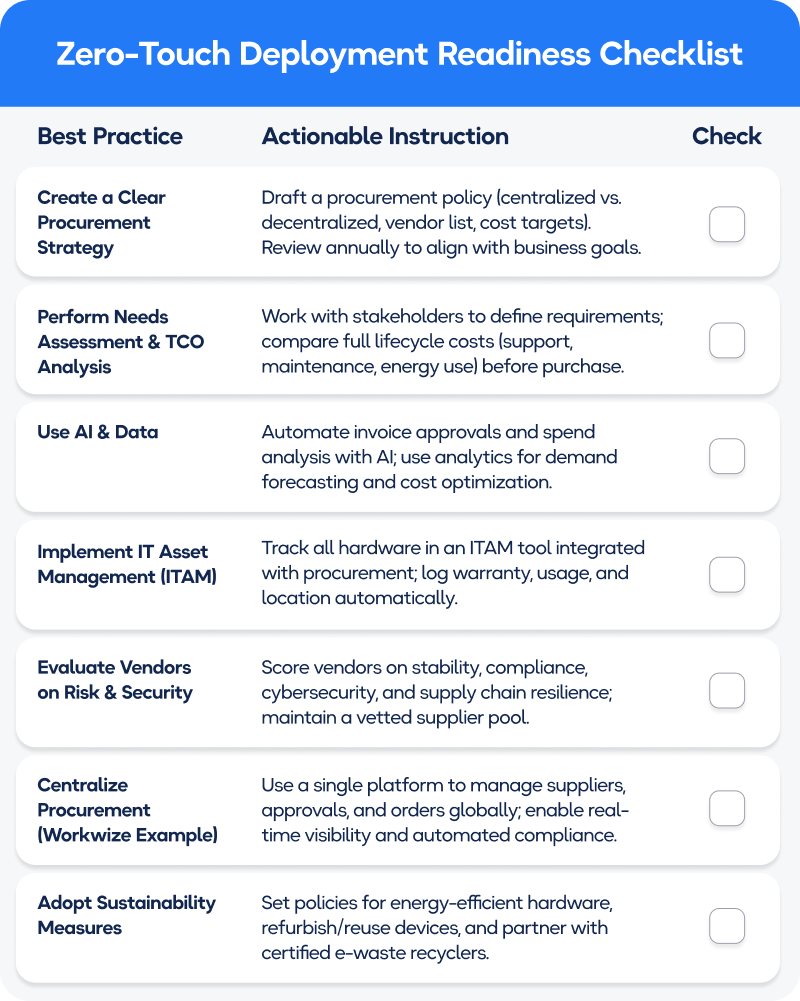

IT Hardware Procurement Best Practices: Checklist

Download this checklist to ensure you don’t miss any critical steps during IT hardware procurement:

Wrapping Up

Procurement might seem like a simple process. But even the smallest issues can create big problems, like employees left without laptops on day one, budget overflows, downtime, compliance issues, and more.

These ripple effects hit productivity, morale, and even your bottom line, unless you follow the best practices and tips to navigate the above challenges.

But if you wish to cross multiple challenges off your list at once, Workwize is your best bet.

With Workwize, you can:

- Choose the right vendors from a global pool of pre-vetted suppliers—no more chasing quotes or relying on unreliable partners.

- Streamline global deliveries, with customs fees and local regulations handled for you.

- Tap into local warehouses, ensuring faster delivery to employees in 100+ countries without extra shipping headaches.

- Control budgets automatically, with built-in spend limits and approval workflows.

- Close the loop with sustainability using refurbish, reuse, and certified recycling options for end-of-life assets.

In short, Workwize doesn’t just solve procurement; it streamlines the entire hardware lifecycle. From vendor selection to disposal, Workwize helps IT teams deliver a seamless, compliant, and cost-effective employee experience every time.

Book a demo now to see how Workwize helps you streamline IT hardware procurement.

FAQs

What is IT hardware procurement?

IT hardware procurement is the process of sourcing, purchasing, and managing the physical technology equipment that a company needs for its operations. This includes everything from computers, laptops, and smartphones to servers, networking gear, and peripherals like printers or monitors.

Why is effective IT hardware procurement crucial?

It saves money, reduces risk, and keeps teams productive. Effective procurement gets the right devices on time, avoids waste, prevents downtime, and supports compliance and sustainability goals—turning purchasing into a strategic advantage, not an admin chore.

How often should we refresh or replace our IT hardware?

Plan a rolling refresh every 3–5 years for user devices (align with warranty). Replace earlier if performance, security updates, or support costs become an issue.

How can we control costs when ordering small quantities?

Batch orders, standardize SKUs, and use large resellers for near-volume pricing. Negotiate perks (shipping, terms), consider leasing with Workwize, and buy certified refurb or last-gen models when suitable. Track annual spend to unlock tiered discounts, even for multiple small purchases.

What is TCO in hardware procurement?

Total Cost of Ownership equals purchase + deployment + energy + support + downtime + end-of-life. Use TCO to compare options fairly and avoid false economies. Sometimes a higher upfront price wins if it lowers support, boosts productivity, and lasts longer.

About the authors:

Simplify IT operations with Workwize

Learn how Workwize makes IT asset management easier and more efficient. Schedule a custom demo today and see the difference.

Recent articles

End-to-End Procurement Services in 2026 | A Guide for Enterprises

Procuring software or hardware across departments and geographies can be a challenging task.

IT Logistics Challenges and Solutions

Managing IT logistics sounds simple; ship devices in, ship them out.

Software for Asset Management: How to Choose and Deploy the Right ITAM Tool

Spreadsheets to track your assets can work when you’re starting out. But, things can get...

Ready to optimize your remote on- and offboardings?

Let’s schedule a short chat and see how we can help!